This website uses its own operating cookies that will be installed. We also use third-party cookies:

- Google Analytics: used to collect statistical information about our website and perform marketing with Adwords.

- Zendesk: necessary for the operation of the online assistance chat.

As long as you don't accept, the third-party cookies will not be installed. More information.

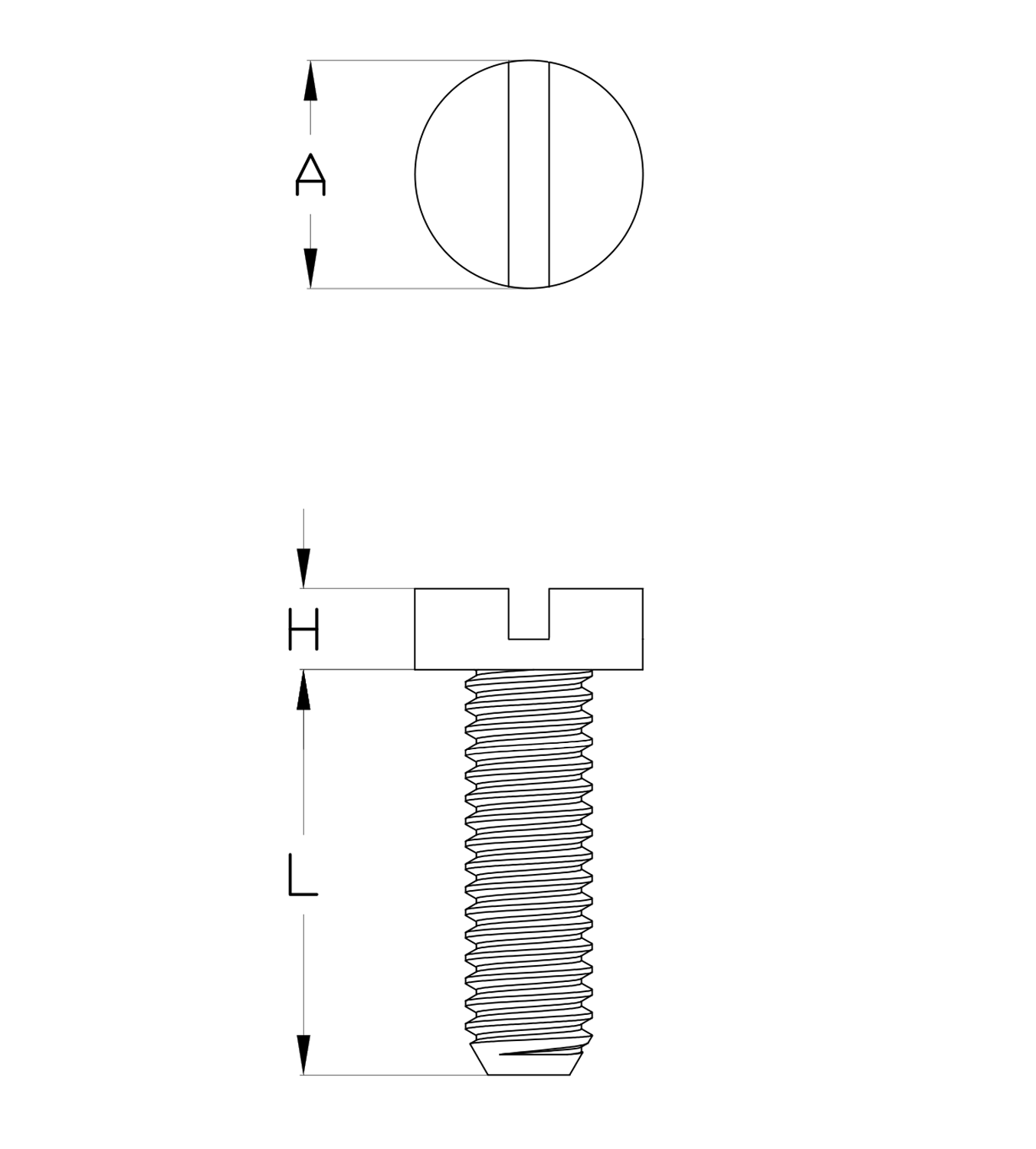

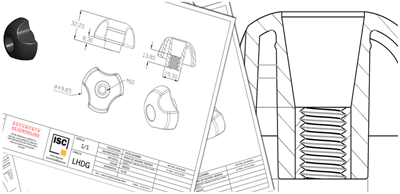

Screws made of PA66 and PA66GF30, high-quality technical materials that combine excellent mechanical strength, good thermal stability, and suitable chemical resistance. They offer a lightweight and reliable alternative to metal screws in a wide range of industrial applications.

Main properties

• Thermal: PA66 up to 100 °C, PA66GF30 up to 120 °C continuous use

• Mechanical: high strength, improved stiffness with glass fiber, good dimensional stability

• Chemical: good resistance to oils, greases, hydrocarbons and common solvents

Advantages over metal screws

• Lower weight without compromising strength

• Corrosion resistant, even in aggressive environments

• Electrically and thermally insulating

• Non-magnetic, non-conductive and spark-free

• Absorb vibrations and reduce noise

• Less maintenance and longer durability under harsh conditions

Ideal for sectors such as electrical, electronics, automotive, construction, HVAC and general industry.

RAL colors manufactured

RAL colors manufactured  Possible to get dyed colors

Possible to get dyed colors

Belgium

Belgium Deutschland

Deutschland España

España France

France Italia

Italia Österreich

Österreich Polska

Polska Portugal

Portugal Schweiz

Schweiz U.K.

U.K. USA

USA World Wide

World Wide